Contract Manufacturing

Dr. Darwin Lab is dedicated to meeting your contract manufacturing needs with enthusiasm. We provide contract manufacturing services to clients worldwide, allowing you to focus on your customers, markets, and marketing endeavors.

Warehousing Capailities

- Raw Materials Sampling (under Airflow Protection Booth – APB)

- Packaging Materials Sampling under APB

- Racking for 1740 Pallets

- Cold Storage x 2 (81 Storage Spaces)

- Flammable Storage (38 Storage Spaces)

- Scheduled Material (18 Storage Spaces)

- Printed Component Storage (440 Storage Spaces)

- Rejection Storage (48 Pallets)

- Stability Chambers 25ºC/ 60% RH, 30ºC/ 65% RH, 40ºC/ 75% RH

- Return Storage (24 Pallets)

- Small Quantities (100 Storage Spaces)

- Large & well controlled Receiving Area

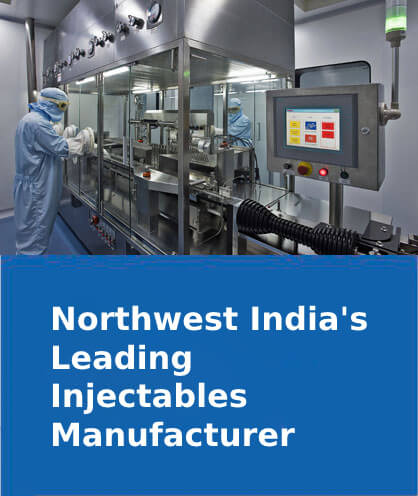

We consistently invest in upgrading our manufacturing facilities, prioritizing the deployment of advanced machinery and the adoption of the latest technologies to comply with 21 CFR regulations. These investments not only enable us to consistently produce high-quality medicines at an affordable cost but also facilitate regulatory audits with relative ease. These distinct advantages position us as the preferred partner for leading global pharmaceutical companies.

Darwin Proficiency

Our expertise lies in operating a high-tech and well-designed manufacturing facility. Notable features of our plant include:

- Compliance to strict riders of WHO cGMP

- Each production area with AHUs (Air Handling Units), Dust Extraction Systems and Dehumidification Units

- Separation of all significant dispensing under takings in each area to avoid cross-contamination

- Constantly improvising Quality Control System

- Setting in each area zone of the plant adjusted in harmony with the requirements of humidity, temperature, filtration, etc

- Authentication of Machinery, Processes and Systems

- Utilization of water which has passed through all tests including microbiology

- Observance to Standard Operating Procedures (SOPs)

- Training on a regular basis to all our employees

- Suitably synchronized plant unit consisting of unidirectional flow of material and work force movement to ensure optimal output

- Optical check-up of ampoules with automated inspection technology

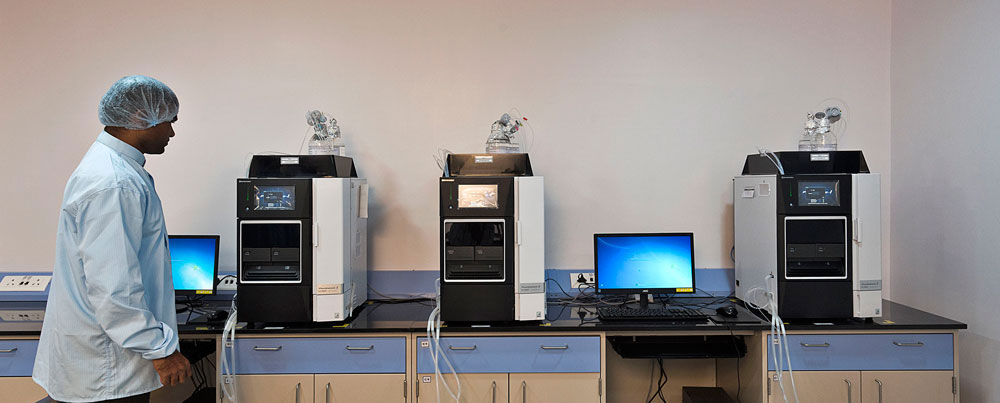

Quality Control Capailities

Darwin boasts a highly-accredited packaging and manufacturing facility, as well as a world-class quality control laboratory. The department is fully equipped to do the following:

- Raw Material Analysis

- Intermediate Analysis

- Finished Product Analysis

- Post Importation Testing

- Microbial Testing

- Environmental Monitoring

- Sterile Testing

- Stability Testing

People – Our Strength

The Dr. Darwin Group is led by a capable, experienced, and driven team of production and quality control staff. Our company is composed of highly educated professionals who excel in their respective departments, including production.

If you have a need for a unique product, Our R&D will develop it for you. Our Unique R&D Strengths:

- Top notch, highly qualified team with burning desire for new product development

- State of the art equipment and best resources

- Ability to turn around products in minimal time frame

On Going R&D

We believe in development of life through research For Dr. Darwin Lab, Research and Development have always been a major component. Spectrums of research are carried out in Dr Darwin Lab, ranging from development of new applications for existing products to upgrading formulation efficiency and improving drug delivery systems. Our independent Research and Development department staffed by well-qualified chemists are involved in a range of research efforts.

Microbiological Laboratory

Dr. Darwin Lab has a Microbiological Laboratory, outfitted and well equipped with the current and high-tech facilities, to

- Conduct routine and in-depth microbiological testing

- Establish product protocols and

- Validate sterilization processes.

Comprehensive evaluations are conducted to assess the quality of raw materials, bulk materials, and finished formulations. Furthermore, we implement ongoing microbiological monitoring of working procedures in process areas, as well as conduct microbiological analysis of our products.

To foster medical advancements, Dr. Darwin Lab has established a state-of-the-art Research and Development Laboratory. This facility will explore promising opportunities for medical breakthroughs. Additionally, we plan to extend the laboratory's services to provide research on a contract basis, further expanding our offerings.

Quality Assurance : Assuring that All Expectations of Safety & Efficacy are Met

Quality Assurance is an integral part of our operations at Dr. Darwin Lab. We have implemented a well-defined quality management system based on industry standards to ensure that our product range maintains exceptional quality standards. Our commitment to quality encompasses all aspects of our operations, including sourcing the finest raw materials, utilizing optimal manufacturing technology, and delivering precise customer requirements consistently.

By adhering to these principles, Dr. Darwin Lab establishes itself as a leading pioneer in the industry, renowned for delivering unparalleled levels of quality. Our experienced and qualified Quality Assurance Team plays a pivotal role in upholding these standards throughout our organization.

Regular Validation

To ensure consistent top-quality product output, we conduct regular validation of key processes, including test methods, water systems, and environmental conditions. Additionally, we perform periodic calibration of all instruments to maintain accuracy and reliability.

Our validation practices extend to various aspects such as air quality, water quality, utilities, methods, processes, vendors, and personnel. This comprehensive approach ensures that all critical components and procedures meet stringent quality standards.

Stringent Vendor Evaluation

To guarantee the highest quality raw materials, we meticulously evaluate and select vendors based on rigorous criteria, including stringent quality standards, product excellence, manufacturing capabilities, service reliability, and prompt delivery. Our thorough vendor evaluation and selection process ensure that we maintain the highest quality standards in our raw material procurement.

Quality at Every Step

At Dr. Darwin Lab, we take pride in our comprehensive Quality Control Laboratory, which adheres to the highest laboratory practices. Equipped with state-of-the-art testing equipment, our lab conducts rigorous quality analytical tests as prescribed by various Pharmacopoeias.

To ensure consistent quality, our dedicated Quality Assurance Department, staffed by qualified personnel, diligently monitors quality parameters. They conduct systematic sampling and testing at every stage, from raw materials to intermediate and finished products. This meticulous approach guarantees that our products meet the stringent quality standards throughout the manufacturing process.

Our Microbiology & Sterility Laboratories are equipped with a Class 10000 Cleanliness environment and an SS horizontal Laminar Air Flow Unit. These state-of-the-art facilities enable us to conduct a comprehensive range of microbiological and sterility validation tests.

Through ongoing and meticulous microbiological monitoring, we ensure the purity of all processes, products, personnel, and production areas. This extensive monitoring and testing process guarantees that our products maintain the highest level of purity and comply with stringent quality standards.

Periodic Self-Audits

In order to stay globally competitive, Dr. Darwin Lab proactively conducts periodic self-assessments through voluntary self-audits of its operations. These self-audits, in addition to adhering to ISO 9001-2008 standards and maintaining an effective Quality Management System, enable us to continuously improve our processes and maintain our competitive edge on an international scale.

Quality Control : An Essential Operation of the Pharmaceutical Industry

- Installing and maintaining effective Quality Management System in accordance with ISO 9001:2015 and continually improve its effectiveness.

- Meeting specific product quality needs of the customer.

- Adherence to CGMP system.

- Training and awareness to employees on Quality Management and CGMP.

- Timely deliveries as agreed with the customer.

- We are also committed to providing required infrastructure and clean work environment.

Dr. Darwin Lab houses a full-fledged Quality Control Laboratory, which follows finest Laboratory Practices and integrates up-to-date, contemporary, and high-tech testing equipment, in order to perform the stringent quality analytical tests prescribed by different Pharmacopoeia. Quality is a way of life at Dr. Darwin Lab.

Manufacturing Strengths

Dr. Darwin Lab manufactures a wide range of Pharmaceutical formulations at its independent, state-of- the-art manufacturing facilities, which also house independent quality control departments and research & development units.

Dr. Darwin Lab has an automated state-of- the-art independent production unit. We are also coming up with a second state of the art sterile facility, specifically targeted for the regulated markets.

Production Capacity

| PRODUCTION UNIT | ANNUAL PRODUCTION CAPACITY |

|---|---|

| Small Volume (Ampoules) Injections | 100 Million |

| Small Volume (Liquid vials) Injections | 20 Million |

| Sterile Dry Powder Injections | 20 Million |

| Ophthalmic Eye/Ear Drops | 20 Million |

| Skin Creams/Ointments/Gel | 25 Million |

| Ophthalmic Eye Ointments | 20 Million |

QUALITY – OUR PROMISE

To guarantee optimal quality, all products undergo thorough testing at various stages of procurement, production, packing, and distribution. Our company maintains an in-house quality control department equipped with state-of-the-art testing facilities to carry out these tests.